Rpm Gearbox, short for revolutions per minute gearbox, plays a crucial role in transferring power and controlling speed in various applications. It acts as an intermediary between the power source and the output shaft, adjusting the rotational speed and torque to meet specific requirements. Understanding how an RPM gearbox functions and its various types is essential for choosing the right one for your needs.

What is an RPM Gearbox and Why is it Important?

An RPM gearbox is a mechanical device designed to change the speed and torque of a rotating shaft. It achieves this by utilizing a series of gears with different numbers of teeth. The input shaft, connected to the power source, rotates at a specific RPM. The gearbox then modifies this rotation through its internal gearing system, delivering a different RPM to the output shaft. This allows for precise control over the speed and torque applied to the driven component.

The importance of an RPM gearbox lies in its ability to optimize power delivery. For instance, in a car, the engine operates efficiently within a specific RPM range. The gearbox allows the car to operate at different speeds while keeping the engine within its optimal range, maximizing fuel efficiency and performance. Similar principles apply to various other applications, from industrial machinery to wind turbines.

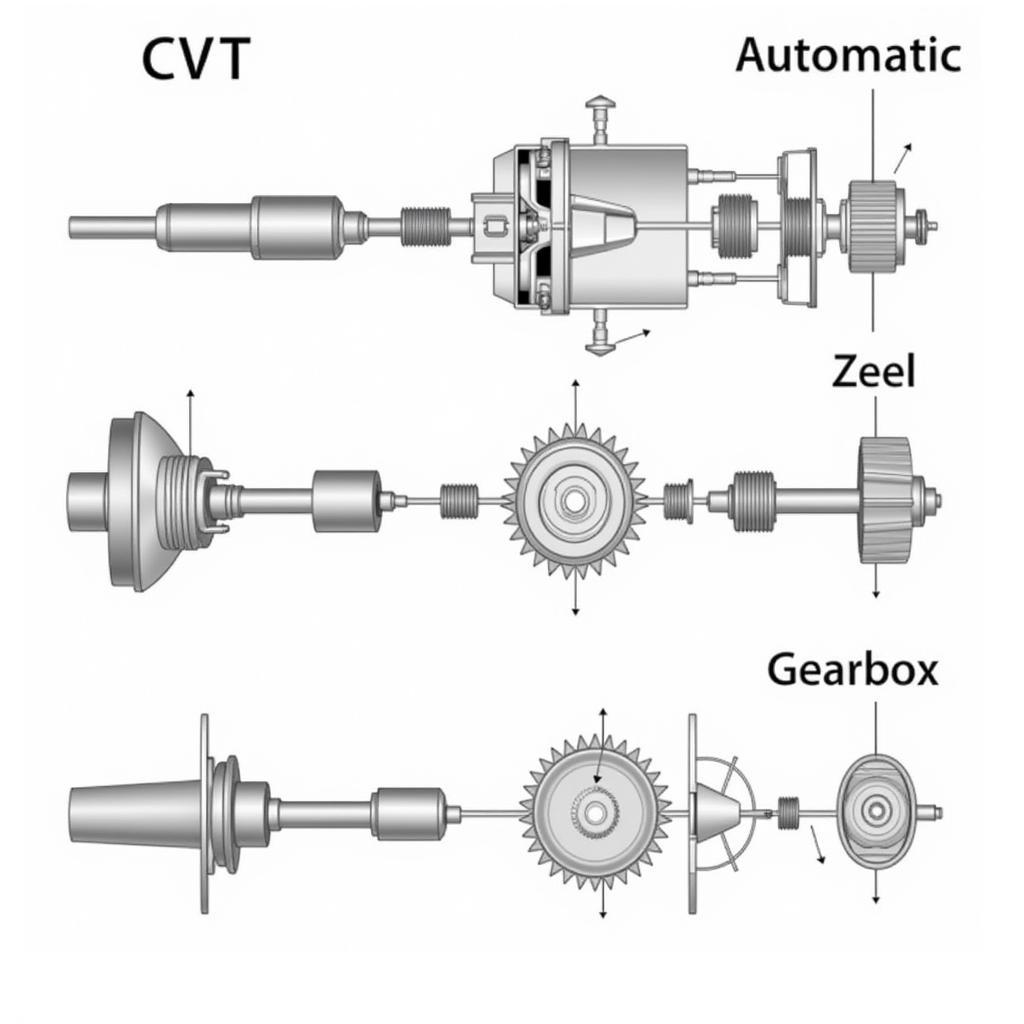

Different Types of RPM Gearboxes

Several types of RPM gearboxes cater to specific needs and applications. Understanding these differences helps in selecting the right gearbox for a particular task.

Manual Gearboxes

Manual gearboxes require the user to manually shift gears to adjust the speed and torque. This type offers direct control over the gear ratios and is commonly found in automobiles and some types of machinery.

Automatic Gearboxes

Automatic gearboxes automatically shift gears based on factors like speed, load, and throttle position. They offer convenience and ease of use, making them popular in modern vehicles.

CVT (Continuously Variable Transmission)

CVT gearboxes offer a seamless and infinite range of gear ratios. They utilize belts or chains on variable-diameter pulleys, allowing for smooth acceleration and optimal engine performance across a wide range of speeds.

Types of RPM Gearboxes

Types of RPM Gearboxes

Key Considerations When Choosing an RPM Gearbox

Choosing the right RPM gearbox requires careful consideration of several factors.

Application Requirements

The specific application dictates the type and specifications of the gearbox. Factors like load, speed, and operating environment play a crucial role in determining the suitable gearbox.

Gear Ratio

The gear ratio represents the relationship between the input and output shaft speeds. Selecting the appropriate gear ratio is critical for achieving the desired output speed and torque.

Efficiency

Gearbox efficiency refers to the percentage of input power that is transmitted to the output shaft. Higher efficiency translates to less power loss and better overall performance.

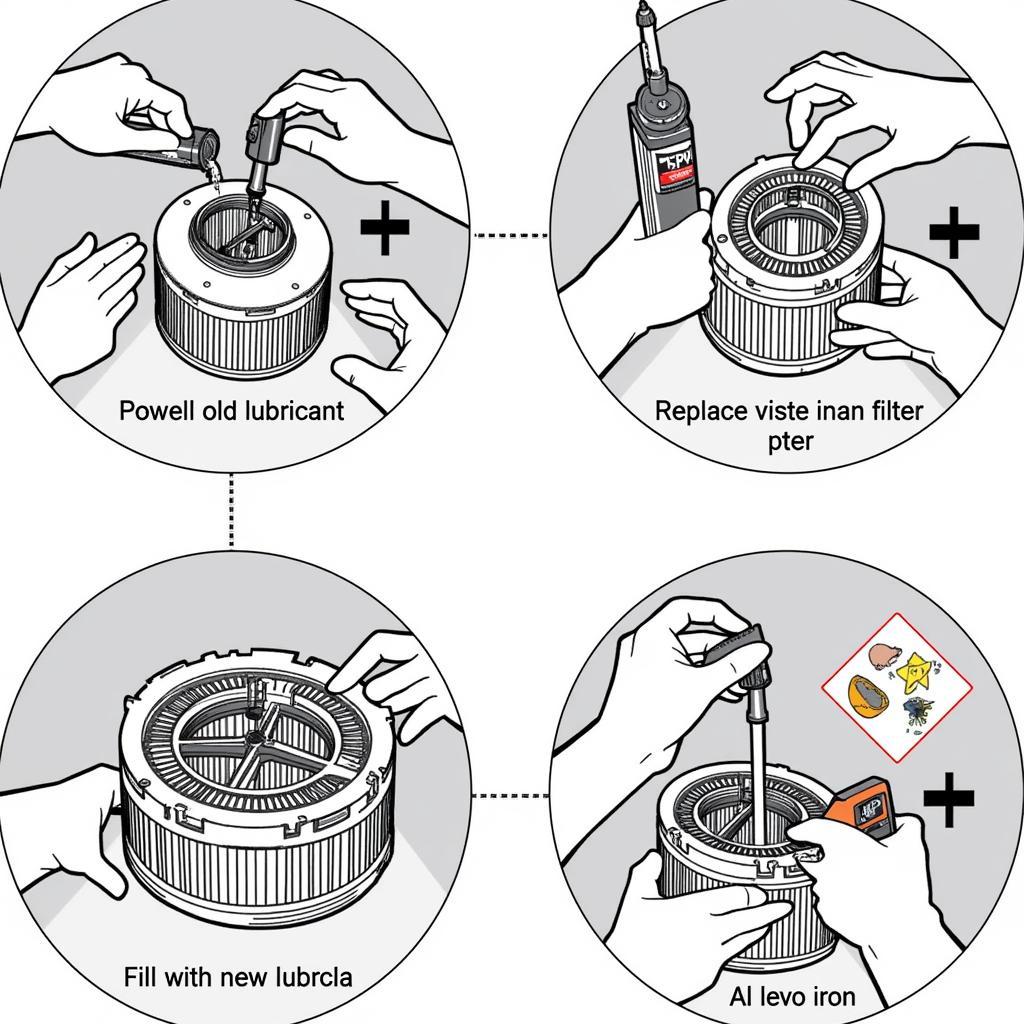

How to Maintain Your RPM Gearbox

Proper maintenance is crucial for ensuring the longevity and performance of an RPM gearbox.

- Regularly check and change the lubricant to prevent wear and tear.

- Inspect for leaks and address any issues promptly.

- Monitor operating temperature and ensure proper cooling.

- Adhere to the manufacturer’s recommended maintenance schedule.

Common RPM Gearbox Troubleshooting

- Unusual noises: Grinding or whining noises can indicate gear wear or damage.

- Difficulty shifting: Problems with shifting gears can be due to clutch issues or internal gearbox problems.

- Leaks: Fluid leaks can lead to reduced lubrication and potential damage.

Maintaining Your RPM Gearbox

Maintaining Your RPM Gearbox

Conclusion

The RPM gearbox is a critical component in many mechanical systems, enabling precise control over speed and torque. Understanding the different types of gearboxes, their applications, and proper maintenance practices is crucial for optimizing performance and longevity. Choosing the right RPM gearbox and maintaining it correctly ensures efficient power transmission and reliable operation in a wide range of applications.

FAQ

- What does RPM stand for in gearbox context? RPM stands for Revolutions Per Minute.

- What is the main function of an RPM gearbox? To change the speed and torque of a rotating shaft.

- What are the different types of RPM gearboxes? Manual, automatic, and CVT.

- How do I choose the right RPM gearbox? Consider application requirements, gear ratio, and efficiency.

- Why is gearbox maintenance important? To ensure longevity and performance.

- What are common signs of gearbox problems? Unusual noises, difficulty shifting, and leaks.

- What is the difference between a manual and automatic gearbox? Manual gearboxes require the user to manually shift gears, while automatic gearboxes shift automatically.

Need support? Contact us 24/7 at Phone Number: 0902476650, Email: [email protected] Or visit us at 139 Đ. Võ Văn Kiệt, Hoà Long, Bà Rịa, Bà Rịa – Vũng Tàu, Việt Nam.