Understanding the Hole Angle Spot Corner is crucial in various fields, from manufacturing and engineering to construction and design. This guide will delve into the intricacies of this concept, exploring its definition, applications, and importance across different industries. We’ll cover everything from basic principles to advanced techniques, ensuring you gain a thorough understanding of the hole angle spot corner.

What is a Hole Angle Spot Corner?

A hole angle spot corner refers to the specific area where a hole intersects with an angled surface or corner. This intersection creates a unique geometric configuration that requires careful consideration during design and fabrication. The hole angle spot corner can be challenging to measure and analyze, especially when dealing with complex shapes and angles.

Importance of Hole Angle Spot Corner in Different Industries

Manufacturing and Engineering

In manufacturing, the precise measurement and control of the hole angle spot corner are essential for ensuring the proper fit and function of components. Incorrectly machined hole angle spot corners can lead to assembly problems, structural weakness, and even product failure. Engineers rely on advanced tools and techniques to analyze these critical areas and ensure they meet the required specifications.

Construction and Design

In construction, understanding the hole angle spot corner is vital for creating stable and durable structures. The accurate placement and alignment of holes in angled beams and supports are crucial for maintaining structural integrity. Designers must carefully consider the hole angle spot corner when planning the construction of buildings, bridges, and other infrastructure.

Challenges and Solutions for Hole Angle Spot Corner Analysis

Analyzing the hole angle spot corner can be challenging due to the complex geometry involved. Traditional measurement methods may not be accurate enough, especially in cases with tight tolerances or intricate shapes. Fortunately, advanced technologies such as 3D scanning and coordinate measuring machines (CMMs) offer precise and reliable solutions for analyzing the hole angle spot corner. These tools allow engineers to capture detailed measurements and create accurate digital models of the part, enabling thorough analysis and optimization.

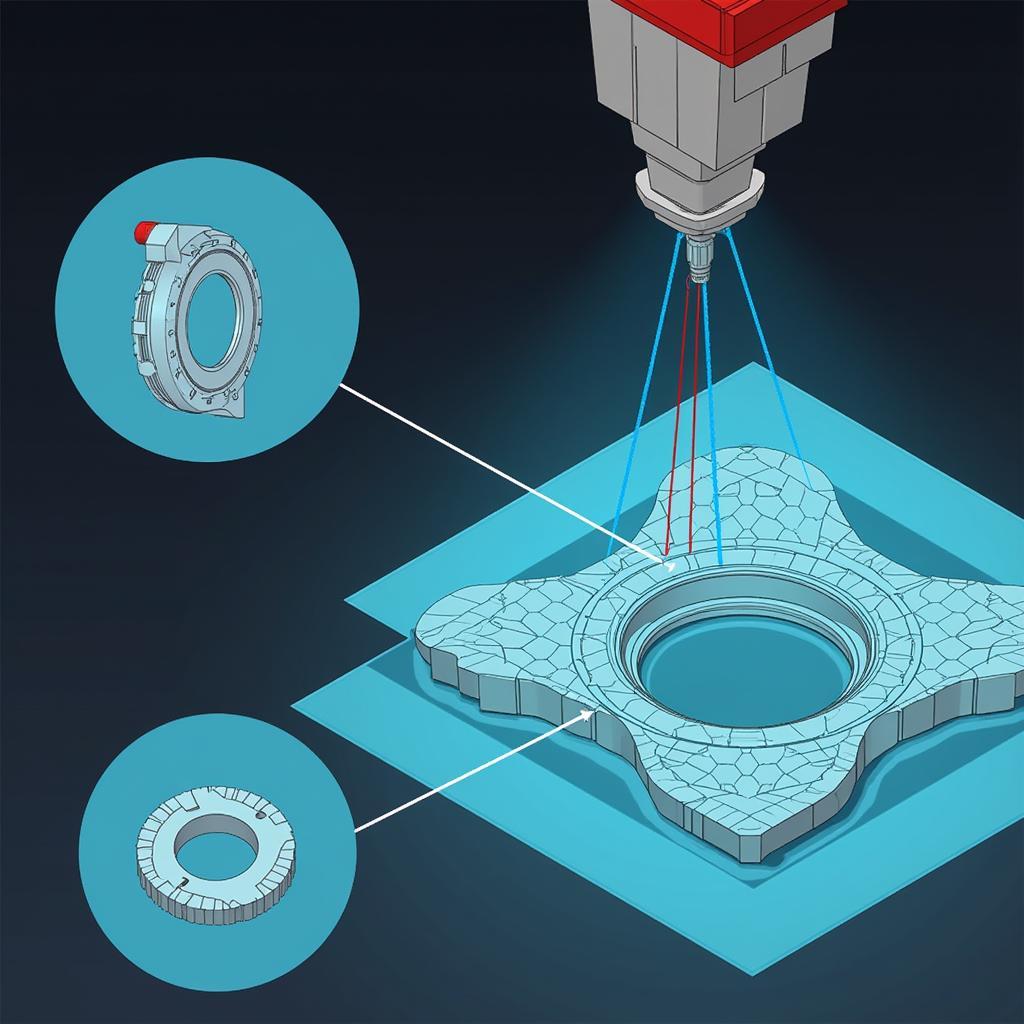

Utilizing 3D Scanning Technology

3D scanning provides a non-contact method for capturing the geometry of the hole angle spot corner. This technology creates a point cloud representing the surface of the part, allowing engineers to analyze the hole angle spot corner in detail.

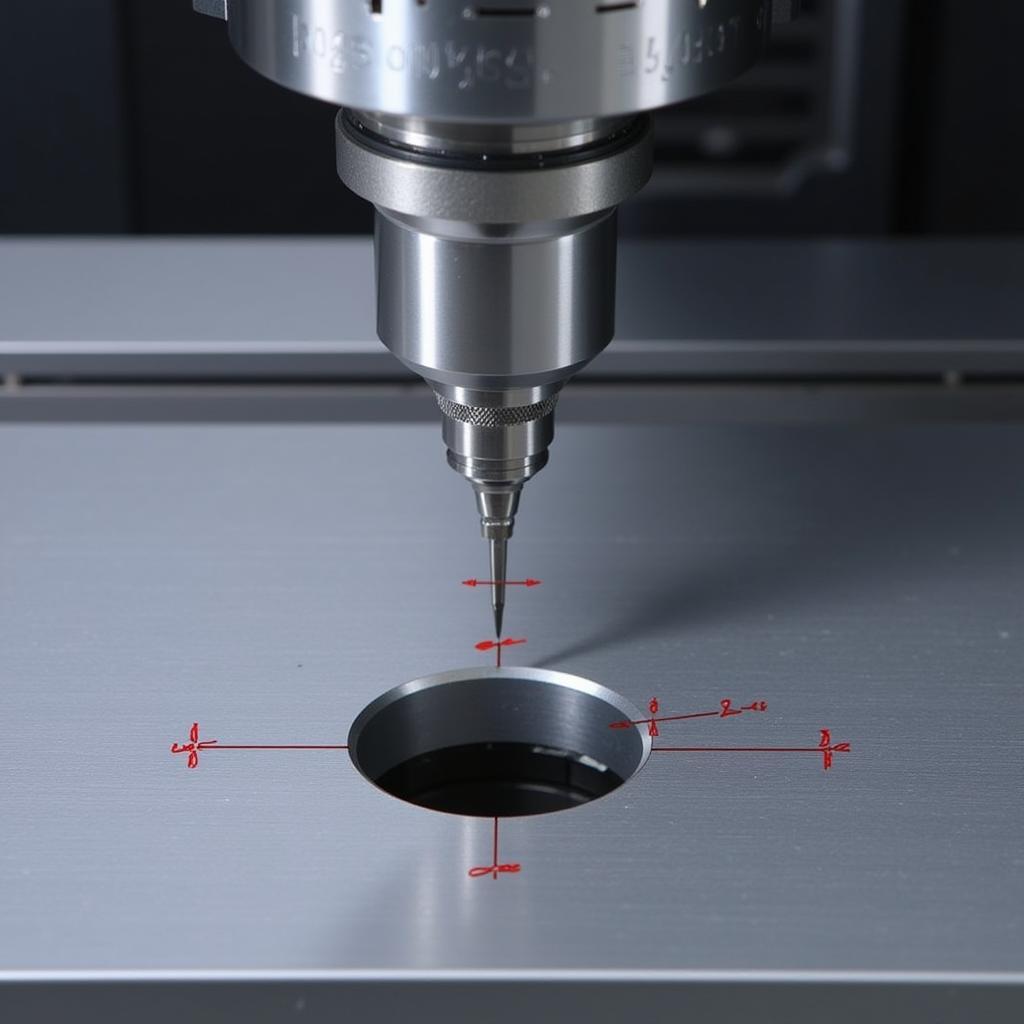

Employing Coordinate Measuring Machines (CMMs)

CMMs offer highly accurate tactile measurements of the hole angle spot corner. These machines use probes to physically contact the part and collect precise dimensional data.

3D Scanning of Hole Angle Spot Corner

3D Scanning of Hole Angle Spot Corner

Best Practices for Hole Angle Spot Corner Design

When designing parts with hole angle spot corners, several best practices should be followed:

- Minimize stress concentrations: The hole angle spot corner can be a point of stress concentration, so it’s essential to minimize sharp angles and incorporate appropriate fillets or radii to distribute the load.

- Consider material properties: The material’s strength and ductility should be taken into account when designing the hole angle spot corner.

- Utilize appropriate tolerances: Specify realistic tolerances for the hole angle spot corner to ensure manufacturability and functionality.

How to Measure a Hole Angle Spot Corner Accurately

Accurate measurement of the hole angle spot corner is essential for quality control and ensuring the proper fit and function of components. Several methods can be used, including:

- Using a Protractor: A protractor can be used to measure the angle between the hole and the surface.

- Employing a CMM: A CMM offers high precision and accuracy for measuring the hole angle spot corner.

- Utilizing 3D Scanning: 3D scanning can capture detailed measurements of the hole angle spot corner.

CMM Measuring Hole Angle Spot Corner

CMM Measuring Hole Angle Spot Corner

Conclusion

The hole angle spot corner is a critical aspect of design and manufacturing in various industries. Understanding its intricacies and applying appropriate measurement and analysis techniques are crucial for ensuring product quality, structural integrity, and overall performance. By following best practices and utilizing advanced technologies, engineers and designers can effectively address the challenges associated with the hole angle spot corner and create robust and reliable products.

FAQs

- What is the most accurate method for measuring a hole angle spot corner? CMMs and 3D scanning offer the highest accuracy for measuring hole angle spot corners.

- Why is the hole angle spot corner important in manufacturing? Accurate hole angle spot corners ensure proper fit and function of components.

- How can stress concentrations at the hole angle spot corner be minimized? Incorporating fillets or radii can help distribute the load and reduce stress concentrations.

- What tools are used to analyze hole angle spot corners? 3D scanning and CMMs are commonly used for analyzing hole angle spot corners.

- What factors should be considered when designing a hole angle spot corner? Material properties, stress concentrations, and tolerances should be considered.

- What are the potential consequences of an incorrectly machined hole angle spot corner? Assembly problems, structural weakness, and product failure can result from incorrect machining.

- How does understanding the hole angle spot corner contribute to structural integrity in construction? Accurate hole placement and alignment in angled supports are crucial for maintaining structural integrity.

Need more assistance? Contact us! Phone: 0902476650, Email: [email protected]. Or visit us at 139 Đ. Võ Văn Kiệt, Hoà Long, Bà Rịa, Bà Rịa – Vũng Tàu, Việt Nam. We have a 24/7 customer support team.