A Fork Wheel, in its simplest form, is a component with forked projections resembling a wheel’s spokes. These forks, or tines, serve various purposes depending on the application. Let’s delve into the fascinating world of fork wheels and explore their diverse uses. trek pure sport

What is a Fork Wheel Used For?

Fork wheels are used across a surprising range of applications, from industrial machinery to delicate scientific instruments. Their versatility stems from their simple yet effective design. These applications often require precise alignment, movement, or control, making the fork wheel an essential component.

Industrial Applications of Fork Wheels

In industrial settings, fork wheels play a crucial role in material handling and automation. They are commonly found in conveyor systems, where they guide and direct the flow of goods. Fork wheels can also be integral parts of robotic arms, providing precise positioning and manipulation.

One example is their use in indexing mechanisms. These mechanisms rely on the precise rotational movement provided by the fork wheel to position parts for assembly or other operations. The robust construction of fork wheels ensures reliable operation even under heavy loads and demanding conditions.

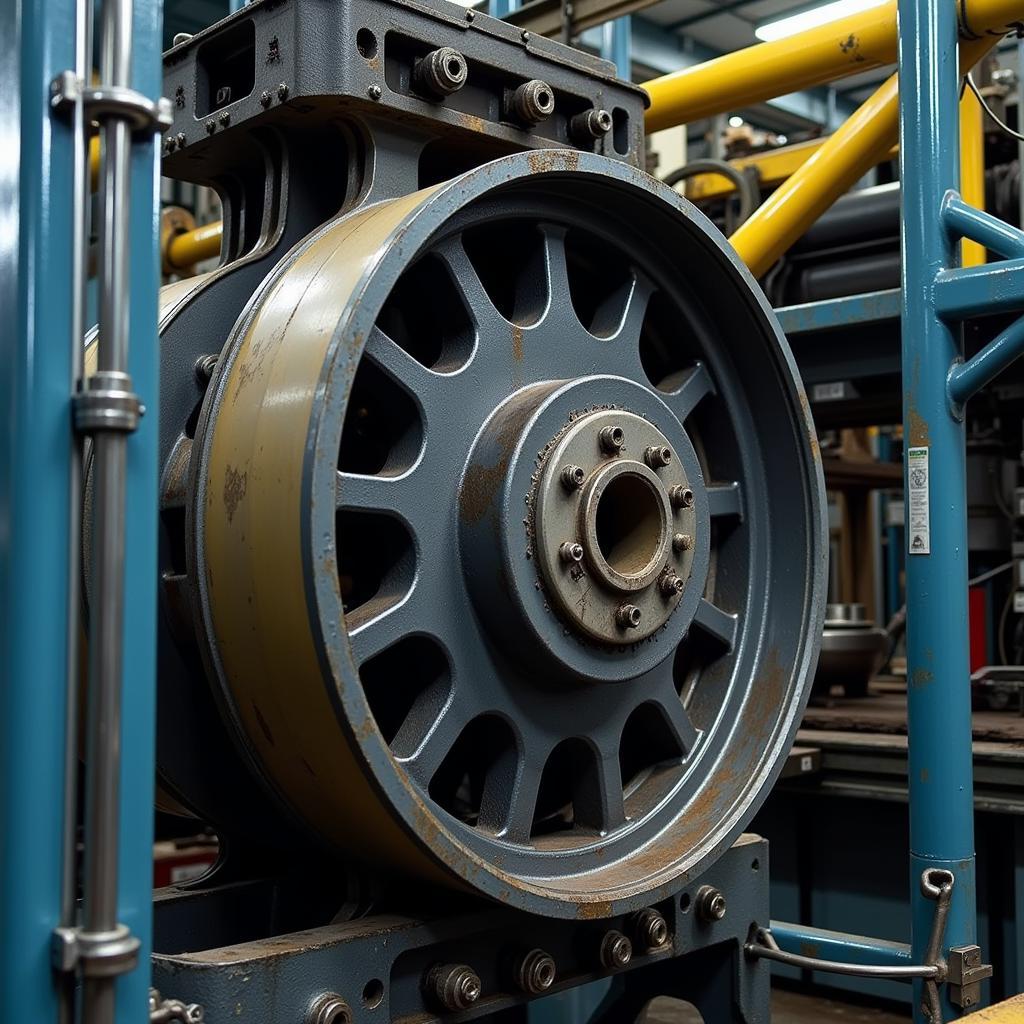

Fork Wheel in Industrial Application

Fork Wheel in Industrial Application

Fork Wheels in Scientific Instruments

Fork wheels are not limited to heavy-duty industrial applications. Their precision and control make them valuable components in scientific instruments. For example, they can be found in optical devices, where they facilitate precise adjustments of mirrors or lenses.

In these delicate applications, the fork wheel’s ability to provide fine-tuned movements is essential. This allows scientists to achieve accurate measurements and observations. The material used for these fork wheels is often chosen for its stability and resistance to environmental factors.

Bicycle Fork Dropouts: A Different Kind of Fork

While not strictly a “fork wheel,” bicycle fork dropouts share a similar naming convention. These are the slots at the bottom of a bicycle fork that hold the wheel axle. They are essential for securing the front wheel and ensuring stable steering. There are various types of dropouts, each offering different advantages in terms of wheel security and adjustability.

Bicycle Fork Dropouts

Bicycle Fork Dropouts

How to Choose the Right Fork Wheel

Selecting the correct fork wheel for a specific application requires careful consideration of several factors. The size, material, and number of tines are crucial aspects that influence performance and durability.

- Size: The diameter and width of the fork wheel determine its load-bearing capacity and compatibility with other components.

- Material: The choice of material depends on the application environment and the required strength and resistance to wear and tear.

- Number of Tines: The number of tines influences the precision and control offered by the fork wheel.

Key Considerations for Fork Wheel Selection

Beyond the basic parameters, additional factors can play a significant role in the selection process. These include:

- Operating Environment: Factors like temperature, humidity, and exposure to chemicals can influence material selection.

- Load Requirements: The expected load and forces acting on the fork wheel will determine the necessary strength and durability.

- Precision Requirements: The level of accuracy needed for the application will dictate the number and design of the tines.

Conclusion

The fork wheel, despite its seemingly simple design, plays a critical role in various applications. From heavy-duty machinery to precision scientific instruments, its versatility makes it an indispensable component. Understanding the different types and choosing the right fork wheel is crucial for optimal performance and reliability. Remember to consider the application requirements and choose a fork wheel that meets the specific needs of your project. trek pure sport

Variety of Fork Wheels

Variety of Fork Wheels

FAQ

-

What are the main applications of fork wheels?

- Fork wheels are commonly used in industrial machinery, scientific instruments, and even in bicycle forks (dropouts).

-

What factors should I consider when choosing a fork wheel?

- Consider the size, material, number of tines, operating environment, load requirements, and precision requirements.

-

What are bicycle fork dropouts?

- Bicycle fork dropouts are the slots at the bottom of the bicycle fork that hold the wheel axle.

-

How does the number of tines affect the fork wheel’s performance?

- The number of tines influences the precision and control of the fork wheel.

-

What materials are commonly used for fork wheels?

- Materials vary depending on the application but can include steel, aluminum, and plastics.

-

How does the operating environment affect the choice of fork wheel material?

- Harsh environments might require more durable materials like stainless steel.

-

Where can I find more information on fork wheels?

- You can find more specific information on fork wheels by searching for industry-specific suppliers or consulting engineering catalogs.

Need help? Contact us 24/7: Phone: 0902476650, Email: [email protected], or visit us at 139 Đ. Võ Văn Kiệt, Hoà Long, Bà Rịa, Bà Rịa – Vũng Tàu, Việt Nam.