EZ Loader hubs are known for their durability and reliability, but even the toughest components eventually require replacement. Whether due to wear and tear, damage, or an upgrade, understanding the process of Ez Loader Hub Replacement is crucial for maintaining your trailer’s performance and safety. This guide provides a comprehensive overview of everything you need to know about replacing your EZ Loader hubs.

Understanding Your EZ Loader Hub

Before diving into the replacement process, it’s essential to understand the different types of EZ Loader hubs and identify which one you have. This will ensure you purchase the correct replacement parts and avoid compatibility issues. EZ Loader offers various hub configurations, including greased and oil bath hubs, each with its own set of advantages. Knowing your hub type is the first step towards a successful replacement.

Identifying Your Hub Type

Determining your EZ Loader hub type is usually straightforward. Look for markings on the hub itself, often indicating the manufacturer and part number. If the markings are unclear, consult your trailer’s owner’s manual or contact EZ Loader directly for assistance. Knowing the specific model and year of your trailer will also help in identifying the correct hub.

Gathering the Necessary Tools and Parts

Once you’ve identified your hub type, gather the necessary tools and replacement parts. This will streamline the replacement process and prevent delays. Commonly required tools include a lug wrench, socket set, hammer, grease gun (for greased hubs), and safety glasses. As for parts, you’ll need a new EZ Loader hub assembly, bearings, seals, and potentially a new spindle depending on the extent of wear or damage.

Choosing the Right Replacement Parts

Selecting high-quality replacement parts is vital for ensuring the longevity and performance of your trailer. While genuine EZ Loader parts are recommended, reputable aftermarket options can also be suitable. Ensure the replacement parts match the specifications of your original hub and bearings.

EZ Loader Hub Replacement Parts

EZ Loader Hub Replacement Parts

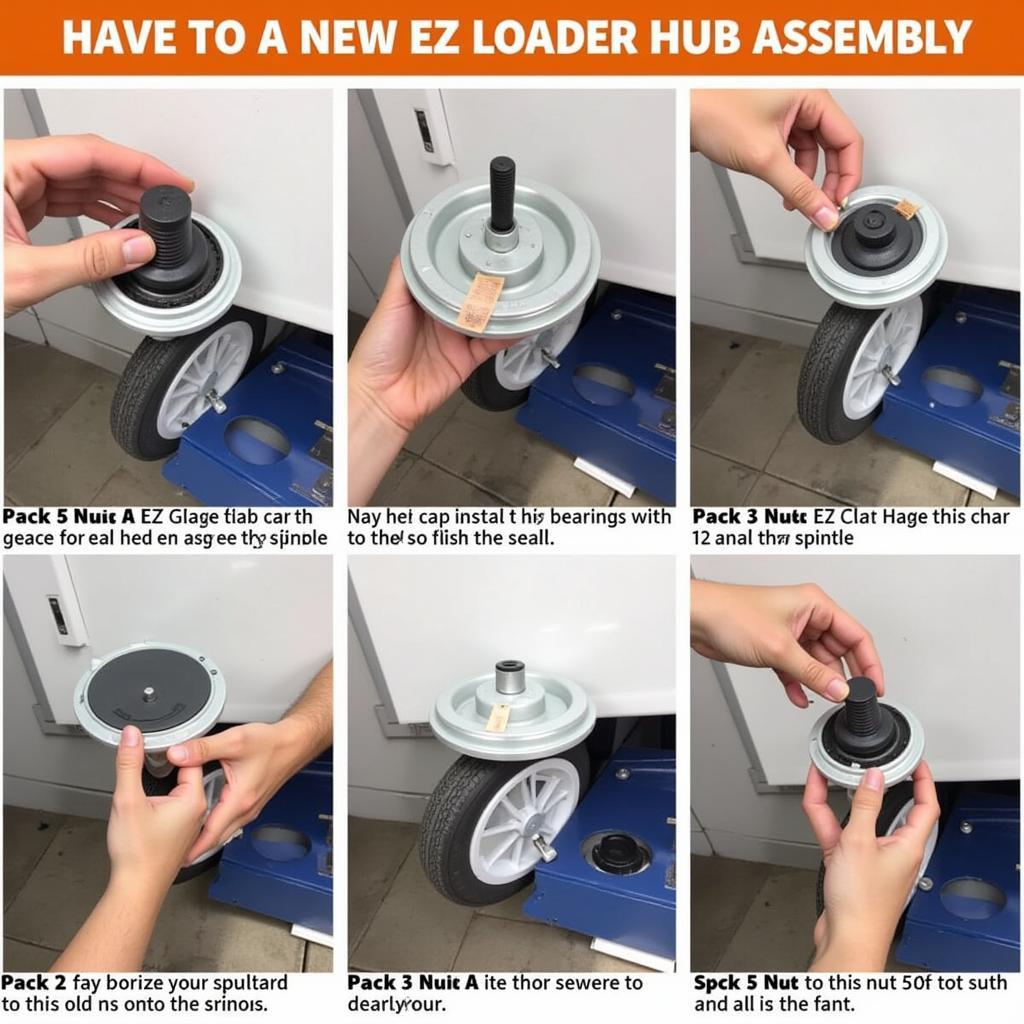

The EZ Loader Hub Replacement Process

With the right tools and parts in hand, you can begin the replacement process. This generally involves removing the wheel and tire, disconnecting the brake components (if applicable), removing the old hub assembly, and installing the new one. Ensure you properly grease or fill the new hub with oil according to the manufacturer’s instructions.

Step-by-Step Guide to Hub Replacement

- Safety First: Securely park your trailer on a level surface and engage the parking brake. Chock the wheels opposite the side you are working on.

- Remove the Wheel and Tire: Use a lug wrench to loosen and remove the lug nuts. Carefully remove the wheel and tire assembly.

- Disconnect the Brakes: If your trailer has brakes, disconnect the brake line and wiring from the backing plate.

- Remove the Hub Assembly: Remove the dust cap, cotter pin, and nut securing the hub to the spindle. Carefully slide the hub assembly off the spindle.

- Install the New Hub Assembly: Pack the new bearings with grease (for greased hubs) or fill the hub with oil (for oil bath hubs). Slide the new hub assembly onto the spindle. Install the new nut, cotter pin, and dust cap.

- Reconnect the Brakes: Reconnect the brake line and wiring to the backing plate.

- Reinstall the Wheel and Tire: Mount the wheel and tire assembly, tightening the lug nuts in a star pattern.

EZ Loader Hub Installation

EZ Loader Hub Installation

Maintaining Your EZ Loader Hubs

Regular maintenance is key to extending the life of your EZ Loader hubs and preventing premature failure. This includes regularly inspecting the hubs for signs of wear or damage, repacking bearings with grease (for greased hubs), and changing the oil (for oil bath hubs) according to the manufacturer’s recommendations.

Conclusion

Replacing your EZ Loader hubs can seem daunting, but with the right knowledge and preparation, it can be a manageable task. By following this guide and adhering to the manufacturer’s instructions, you can ensure a successful hub replacement and keep your trailer rolling smoothly and safely. Regular maintenance is crucial for extending the life of your new hubs and preventing future issues. If you are unsure about any part of the process, consult a qualified trailer mechanic.

FAQ

- How often should I replace my EZ Loader hubs? There’s no set timeframe, but inspect them annually or more frequently if used in harsh conditions.

- Can I replace just the bearings, or do I need a whole new hub? It depends on the extent of wear or damage. Sometimes, only the bearings and seals need replacing.

- What are the signs of a bad EZ Loader hub? Excessive noise, wobbling wheels, and overheating are common signs.

- Where can I buy EZ Loader hub replacement parts? From authorized dealers, online retailers, or directly from EZ Loader.

- Can I replace my EZ Loader hubs myself? Yes, with the right tools and knowledge. If unsure, consult a professional.

- What type of grease should I use for my EZ Loader hubs? Consult your owner’s manual or contact EZ Loader for specific recommendations.

- How do I know if my EZ Loader hubs are greased or oil bath? Look for markings on the hub or consult your owner’s manual.

Common EZ Loader Hub Replacement Scenarios

- Bearing Failure: Noisy hubs, grinding sounds, and wobbling wheels often indicate bearing failure, necessitating hub replacement.

- Seal Damage: Leaking grease or oil can be a sign of seal damage, potentially leading to bearing failure if not addressed.

- Hub Overheating: Excessive heat can damage the hub and bearings, requiring replacement.

- Physical Damage: Impacts or corrosion can compromise the hub’s integrity, necessitating replacement.

Further Reading and Resources

- EZ Loader Official Website

- Trailer Maintenance Tips and Tricks

Need help? Contact us at Phone: 0902476650, Email: [email protected], or visit us at 139 Đ. Võ Văn Kiệt, Hoà Long, Bà Rịa, Bà Rịa – Vũng Tàu, Việt Nam. Our customer support team is available 24/7.