Deposito De Metales, or metal deposition, is a fundamental process with wide-ranging applications across various industries. From creating protective coatings to fabricating intricate electronic components, understanding the nuances of metal deposition is crucial. This guide explores the different types, benefits, and applications of metal deposition, providing valuable insights for both novices and seasoned professionals.

Exploring the Types of Deposito de Metales

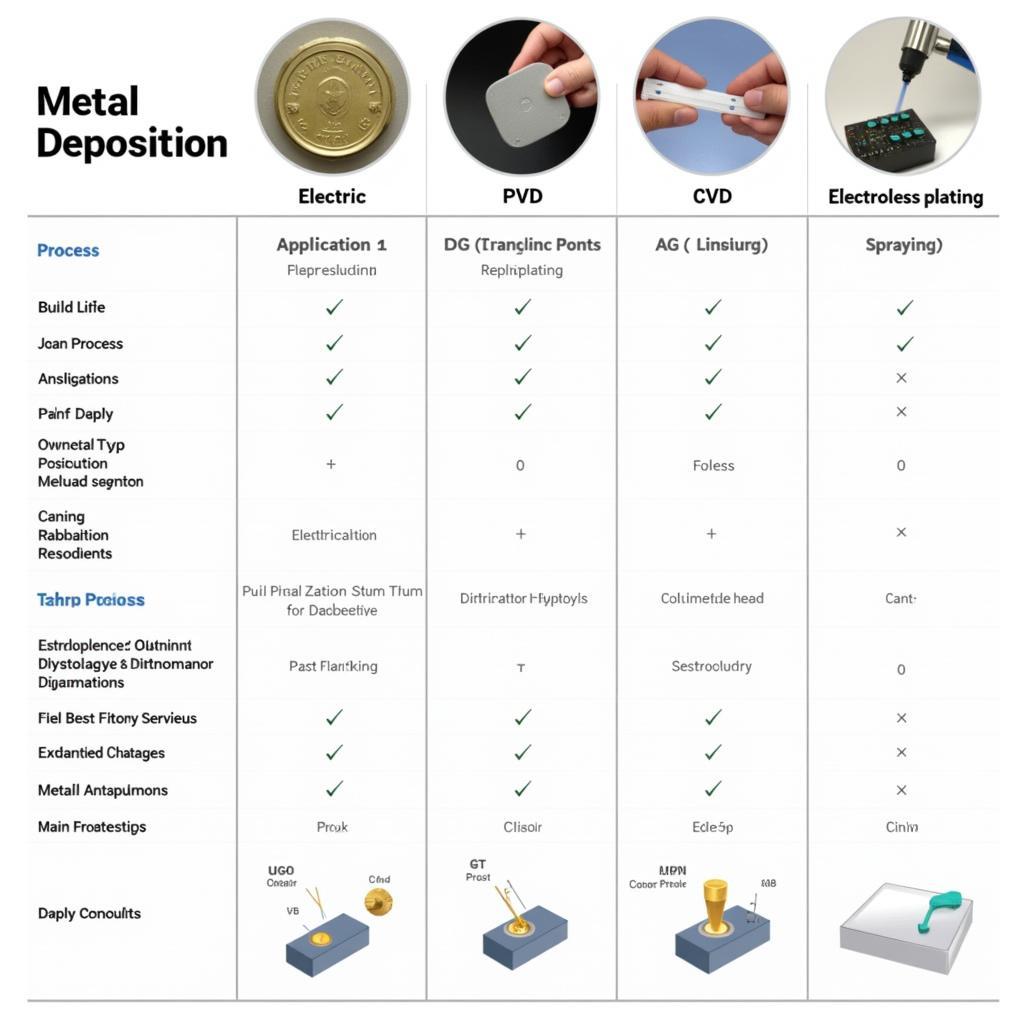

There are various methods for achieving metal deposition, each with its own advantages and limitations. Some of the most common techniques include:

- Electroplating: This method uses an electric current to deposit a thin layer of metal onto a conductive surface. It’s widely used for decorative and protective purposes, enhancing the appearance and durability of various objects.

- Physical Vapor Deposition (PVD): PVD involves vaporizing a metal source and then condensing it onto a substrate. This technique creates thin, uniform coatings with excellent adhesion and wear resistance.

- Chemical Vapor Deposition (CVD): CVD uses chemical reactions to deposit metal onto a surface. It’s often used for creating high-performance coatings in demanding applications like aerospace and semiconductors.

- Electroless Plating: This autocatalytic process deposits metal without the use of an external current source. It’s particularly useful for coating complex shapes and non-conductive materials.

- Spraying: Thermal spraying and other spraying techniques propel molten or semi-molten metal onto a substrate, creating a thick, protective coating often used for corrosion resistance.

Comparing Different Metal Deposition Techniques

Comparing Different Metal Deposition Techniques

Benefits of Deposito de Metales

Metal deposition offers a range of benefits that enhance the properties and functionality of various materials. These include:

- Enhanced Corrosion Resistance: Metal coatings act as a barrier against corrosive elements, extending the lifespan of underlying materials.

- Improved Wear Resistance: Hard metal coatings increase the durability and resistance to abrasion of tools and components.

- Enhanced Aesthetics: Decorative coatings can improve the appearance of products, adding value and appeal.

- Increased Conductivity: Metal deposition can enhance the electrical conductivity of surfaces, crucial in electronics applications.

- Improved Solderability: Certain metal coatings facilitate the soldering process, essential for electronic assembly.

Applications of Deposito de Metales Across Industries

Deposito de metales plays a critical role in a diverse range of industries:

- Automotive: Protective coatings for car parts, decorative finishes for wheels, and electrical components.

- Aerospace: High-performance coatings for turbine blades, corrosion protection for aircraft structures.

- Electronics: Creating conductive pathways on circuit boards, manufacturing semiconductors.

- Medical: Implants, surgical instruments, and dental prosthetics often benefit from biocompatible metal coatings.

- Jewelry: Electroplating with precious metals like gold and silver enhances the value and appearance of jewelry.

Industrial Applications of Metal Deposition

Industrial Applications of Metal Deposition

Choosing the Right Deposito de Metales Method

Selecting the appropriate metal deposition technique depends on various factors, including:

- Material Properties: The substrate material influences the choice of method.

- Desired Coating Thickness: Different techniques offer varying coating thicknesses.

- Performance Requirements: Specific applications demand specific coating properties like hardness, corrosion resistance, or conductivity.

- Cost Considerations: Different methods vary in cost and complexity.

What are the common challenges with deposito de metales?

Common challenges include ensuring uniform coating thickness, managing adhesion issues, and controlling the deposition rate.

Conclusion

Deposito de metales is a crucial process that enhances the properties and functionality of materials across various industries. Understanding the different techniques, benefits, and applications can help businesses and individuals choose the most effective method for their specific needs. By carefully considering the factors involved, you can leverage the power of metal deposition to improve performance, durability, and aesthetics.

FAQ

- What is the difference between electroplating and electroless plating?

- What are the environmental implications of metal deposition processes?

- How do I choose the right metal coating for my application?

- What are the latest advancements in metal deposition technology?

- How can I improve the adhesion of a metal coating?

- What is the typical lifespan of a metal coating?

- How do I maintain and care for metal-coated surfaces?

Contact us for expert support with your metal deposition needs.

Call us at: 0902476650

Email us at: [email protected]

Visit us at: 139 Đ. Võ Văn Kiệt, Hoà Long, Bà Rịa, Bà Rịa – Vũng Tàu, Việt Nam. We have a 24/7 customer support team.