Understanding the Different Types of A&M Support Brackets

A&M support brackets are categorized based on their shape, material, and load-bearing capacity. Choosing the correct type depends on the specific application and the weight it needs to support.

- L-shaped brackets: These are the most common type, offering excellent support for shelves, signs, and other structures against a vertical surface.

- T-shaped brackets: Ideal for supporting beams and other horizontal elements, providing stability and preventing sagging.

- U-shaped brackets: Designed for heavier loads, these brackets offer increased strength and support for larger structures.

- Custom-designed brackets: For specialized applications, custom-designed brackets cater to unique requirements, ensuring a perfect fit and optimal performance.

Different materials like steel, aluminum, and plastic are used to manufacture A&M support brackets, each with its own advantages and disadvantages. Steel offers high strength and durability, while aluminum is lightweight and corrosion-resistant. Plastic brackets are cost-effective but have lower load-bearing capacity.

Choosing the Right A&M Support Bracket for Your Needs

Selecting the appropriate A&M support bracket involves considering several factors. The weight of the object being supported is paramount, as is the type of surface the bracket will be attached to. Environmental factors, such as exposure to moisture or extreme temperatures, also play a role.

Considering Load Capacity and Material

The load capacity of the bracket must exceed the weight of the object it will support. Using a bracket with insufficient capacity can lead to structural failure. The material choice depends on the environment and the desired aesthetic. For outdoor applications, stainless steel or aluminum brackets are preferable due to their corrosion resistance.

Evaluating Surface Compatibility

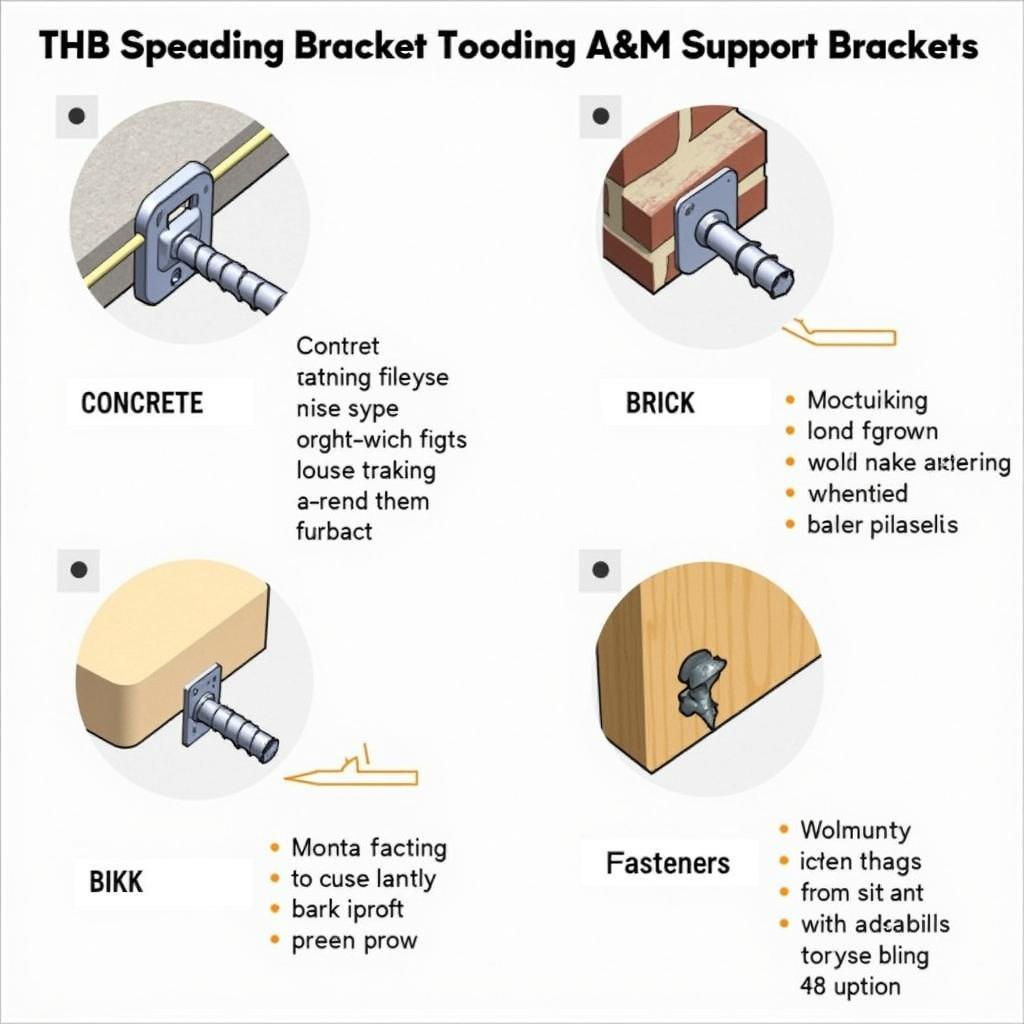

Different surfaces require different types of fasteners. Ensure the chosen bracket and fasteners are compatible with the surface material. For example, concrete walls require different anchors than wooden studs.

A&M Support Bracket Installation on Different Surfaces

A&M Support Bracket Installation on Different Surfaces

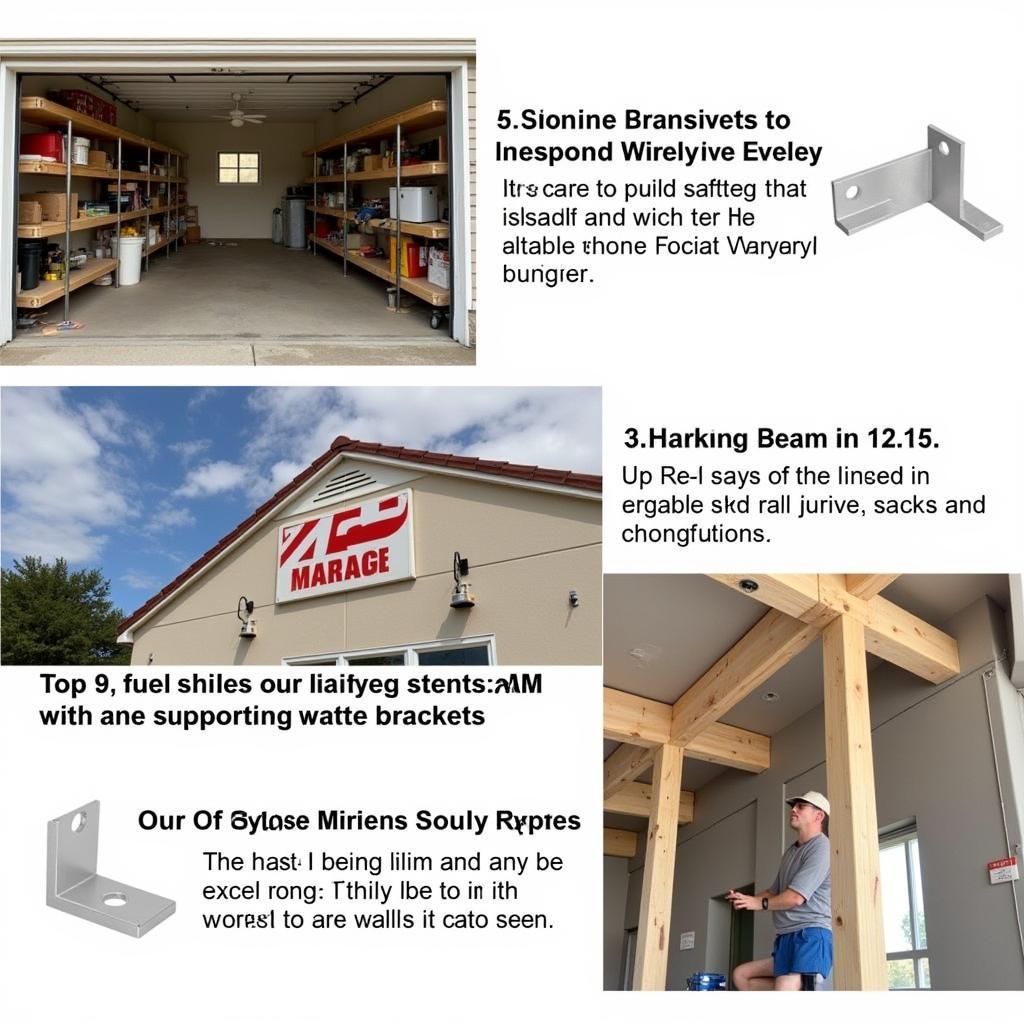

Installing A&M Support Brackets: A Step-by-Step Guide

Proper installation is crucial for the safety and effectiveness of A&M support brackets. Following these steps will ensure a secure and stable installation.

- Measure and mark: Carefully measure and mark the desired location for the bracket.

- Pre-drill holes: If necessary, pre-drill holes in the mounting surface.

- Attach the bracket: Secure the bracket to the surface using appropriate fasteners.

- Verify stability: Check the bracket’s stability by applying pressure.

- Mount the object: Mount the object being supported onto the bracket, ensuring it is securely attached.

Tips for a Successful Installation

- Use a level to ensure the bracket is installed straight.

- Use appropriate safety equipment, such as eye protection and gloves.

- Consult a professional if you are unsure about any aspect of the installation process.

“Proper installation is key to maximizing the lifespan and effectiveness of your A&M support brackets,” advises John Smith, a structural engineer with 20 years of experience. “Taking the time to carefully measure, select the correct fasteners, and follow the installation steps will ensure a safe and stable structure.”

Applications of A&M Support Brackets

Applications of A&M Support Brackets

Conclusion: Ensuring Stability and Support with A&M Support Brackets

A&M support brackets are essential components for providing stability and support in a wide range of applications. By understanding the different types, choosing the right bracket for your needs, and following proper installation procedures, you can ensure the safety and longevity of your structures. Remember, investing in quality A&M support brackets and taking the time for a precise installation will pay off in the long run.

FAQ

-

What are the most common types of A&M support brackets? L-shaped, T-shaped, and U-shaped are the most common types.

-

How do I choose the right size bracket? Consider the weight of the object being supported and the type of surface the bracket will be attached to.

-

What materials are A&M support brackets made of? Common materials include steel, aluminum, and plastic.

-

How do I install A&M support brackets? Follow the manufacturer’s instructions and ensure the bracket is securely attached to the surface.

-

Where can I buy A&M support brackets? They are available at most hardware stores and online retailers.

-

What are the benefits of using A&M support brackets? They provide stability, support, and increased safety for various structures.

-

Can I use A&M support brackets outdoors? Yes, choose brackets made of corrosion-resistant materials like stainless steel or aluminum.

Need further assistance with A&M support brackets? Contact us at Phone Number: 0902476650, Email: [email protected] or visit us at 139 Đ. Võ Văn Kiệt, Hoà Long, Bà Rịa, Bà Rịa – Vũng Tàu, Việt Nam. We have a 24/7 customer support team.